Qualcomm

Over my first year, I worked with a small team to improve the design of a third-party pick and place machine used for high-volume validation testing. By providing recommendations on mechanical improvements and reverse engineering the original PLC Firmware to fix major bugs and add major QOL sequences, I helped reduce the false-failure rate of the robot from 60% down to <2%.

Once the project was stable, I moved onto the Post-Silicon Power Validation team, focusing on Power validation. My primary role is low-power mode validation, working closely with designers, content teams, and project leads to ensure that the minimum power consumption specs which are presented to customers are met. In addition, my scope has expanded to include power debug, peak power validation, thermal validation, and power-performance analysis.

Snapdragon 855: Low Power Mode (LPM) Validation.

Snapdragon 865: LPM Validation. Power Debug. Peak Power Validation.

Snapdragon 888: LPM Validation. Power Debug. Thermal Validation.

Cloud AI 100: Power Performance Analysis.

Next-Gen Flagship Mobile SOC: SVE Post-Si Power and Thermal Debug Lead. High Volume Power Automation.

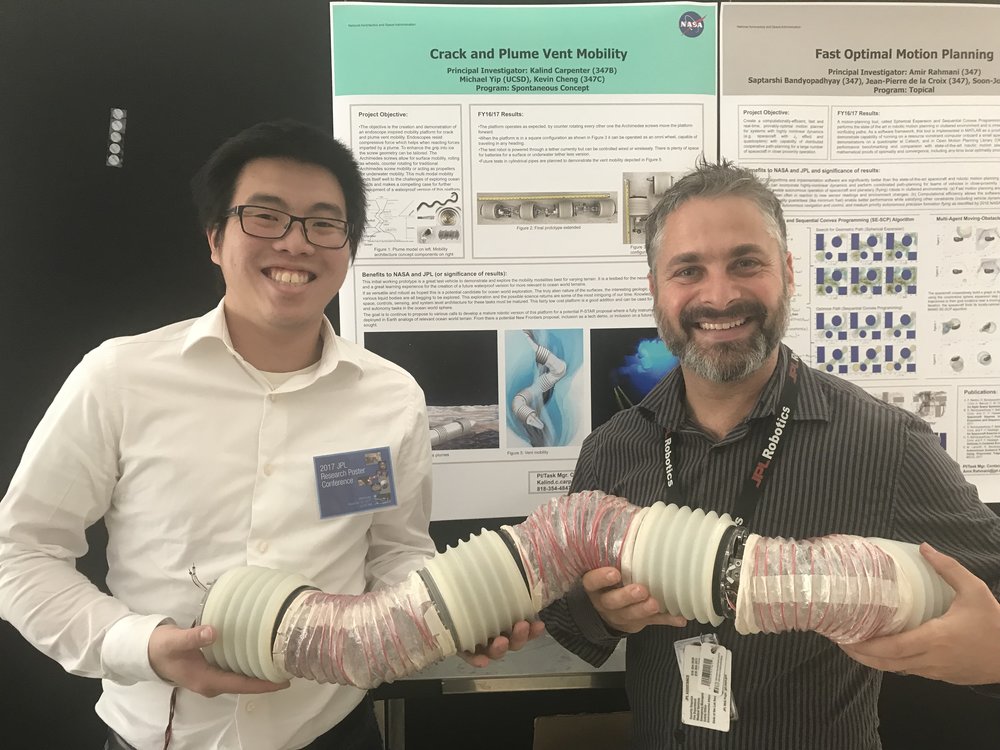

JPL COLLABORATION

The ARCLab and JPL collaborated in order to create a large-scale version of our Screw-Propelled Endoscopic Robot which would be able to explore the plumes of Saturn’s icy moon Enceladus. Within 3 months, we were able to develop a prototype of the robot to present at the 2017 JPL Poster Conference.

The objective is the creation and demonstration of an endoscope inspired mobility platform for crack and plume vent mobility. Endoscopes resist compressive force which helps when reacting forces imparted by a plume. To enhance the grip into ice the screw geometry can be tailored. The Archimedes screws allow for surface mobility, rolling as wheels, counter rotating for traditional Archimedes screw mobility or acting as propellers for underwater mobility. This multi modal mobility lends itself well to the challenges of exploring ocean worlds and makes a compelling case for further development of a waterproof version of this platform.

Media: Videos Google Drive

ARCLAB

The Advanced Robotics and Controls Lab (ARClab), led by Dr. Michael Yip, focuses on developing intelligent algorithms and controls for robotic systems.

Along with Dmitrii Votintcev, an Electrical Engineering Graduate Student, I have been developing a modular screw-propulsion based endoscopic robot. Conventional endoscopes are designed to be flex and conform as they are inserted deeper into the patient. In order for them to continue past a bend in the colon, the doctor is required to push against the wall until the endoscope is able to progress, causing the patient discomfort. In order to resolve this, we have proposed a screw-propulsion based system which is able to pull itself along by rotating the threads along the robot. By combining this with a modular design, we are able to create a variable-width and length endoscope which can not only traverse more complicated paths than a conventional endoscope, but can also be adapted to it’s specific environment.

Media: Videos Google Photos